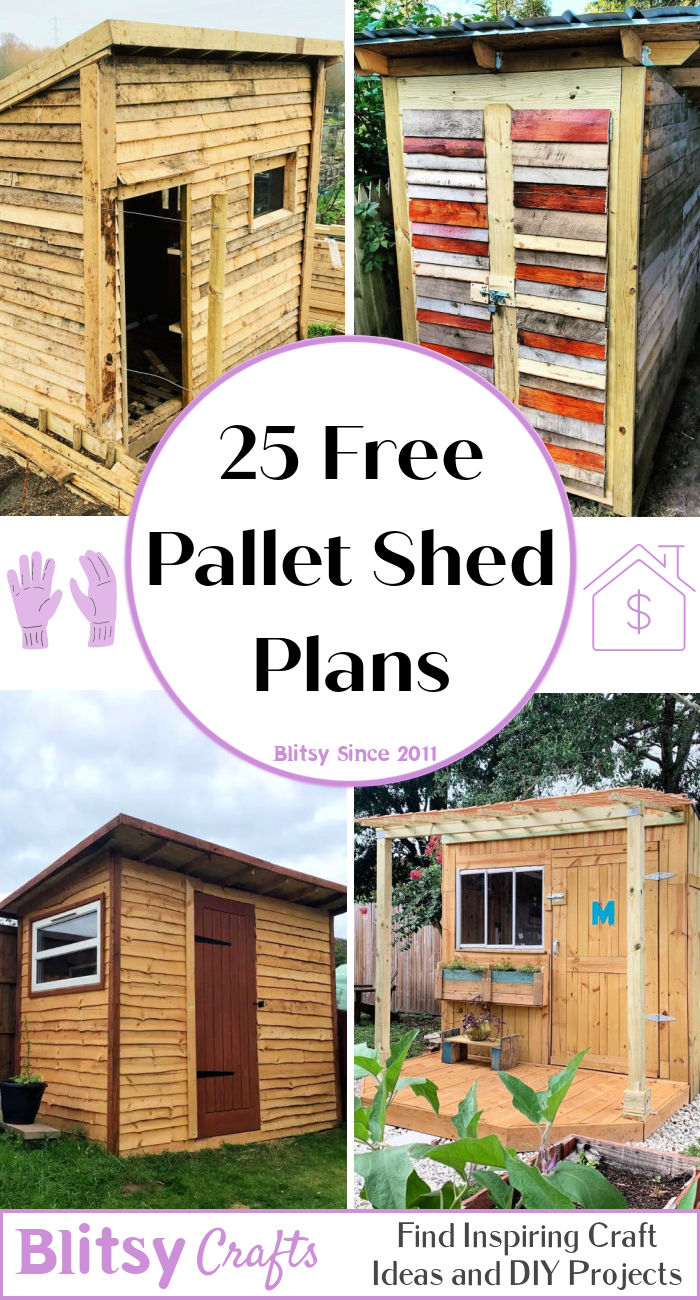

Free Pallet Shed Plans: How to Build a Functional Shed for Your Garden

Constructing a garden shed offers invaluable storage space for gardening tools, equipment, and seasonal items. While pre-fabricated sheds provide convenience, their cost can be prohibitive. A resourceful and cost-effective alternative lies in utilizing reclaimed pallets to build a sturdy and functional shed. This detailed guide provides comprehensive free pallet shed plans, enabling even novice DIY enthusiasts to construct their own garden storage solution.

Assessing Your Needs and Site Preparation

Before embarking on the construction process, a thorough assessment of your specific needs and site preparation is crucial. This initial phase lays the foundation for a successful project.

Determining Shed Dimensions and Functionality

The first step involves determining the optimal dimensions of your pallet shed. Consider the amount of storage space required. Will you primarily store gardening tools, or will the shed house larger items such as lawnmowers or bicycles? Accurately estimating the necessary internal volume dictates the shed's overall footprint and height. Sketch a simple design outlining the intended layout, including shelves, hanging racks, and any other desired features. Remember to account for adequate aisle space for easy maneuverability within the shed.

Site Selection and Ground Preparation

The location of your shed significantly influences its longevity and usability. Choose a level, well-drained area that receives adequate sunlight for natural ventilation and minimizes potential dampness. Clear the selected site of vegetation, debris, and any obstacles. Assess the ground's stability; uneven terrain can compromise the shed's structural integrity. Consider laying a gravel base for improved drainage and a level foundation. This foundational layer prevents direct contact with the soil, minimizing moisture absorption by the pallet structure.

Sourcing and Preparing Pallets

The success of this project hinges on securing suitable pallets. The quality of the pallets directly impacts the shed's durability and longevity. Careful selection and preparation are critical stages.

Selecting Appropriate Pallets

Source high-quality pallets. Avoid pallets exhibiting significant damage, rot, or pest infestation. Ideally, opt for heat-treated pallets (marked with "HT") rather than those chemically treated (marked with "MB"). Heat-treated pallets are safer for environmental and health reasons. Inspect each pallet meticulously for broken or loose boards, ensuring structural soundness. Prioritize pallets of consistent dimensions to simplify construction.

Cleaning and Disassembly

Once suitable pallets are acquired, thorough cleaning is necessary. Use a stiff brush and appropriate cleaning solution to remove dirt, debris, and any remaining product residue. Carefully disassemble the pallets, removing nails and screws. Wear protective gloves and eyewear during this process. Inspect each board for damage and discard any compromised components. Organize the reclaimed boards by size and condition, preparing them for assembly.

Constructing the Pallet Shed Frame

The frame forms the structural backbone of the shed. Careful construction ensures stability and longevity.

Creating the Base Frame

Construct the base frame using the longest and strongest pallet boards. Create a rectangular frame according to the predetermined dimensions of your shed. Secure the joints using appropriate screws or galvanized nails. Ensure the frame is perfectly square and level. Consider reinforcing the corners with additional bracing for added stability.

Erecting the Walls

Assemble the wall sections using the remaining pallet boards. Position the boards vertically, creating a sturdy wall structure. Use additional bracing and cross-members to enhance strength and rigidity. You can create multiple wall sections individually and then connect them to the base frame. Ensure the wall sections are plumb and aligned with the base frame. Securely fasten the wall sections to the base frame using screws or nails.

Building the Roof Frame

The roof frame should be designed to withstand the elements. A simple gable roof is a practical and aesthetically pleasing option. Construct two triangular roof sections, using strong boards to create the rafters. Connect the rafters at the ridge and securely attach them to the top of the wall sections. Consider adding additional supports for enhanced stability, particularly in areas prone to high winds.

Completing the Shed: Roofing, Siding, and Finishing Touches

Once the frame is complete, focus on roofing, siding, and final touches that enhance functionality and aesthetics.

Roofing the Shed

Cover the roof frame with a suitable roofing material. While reclaimed pallets can be used for a rustic look, a more durable and weather-resistant option is recommended. Consider using roofing felt, corrugated metal sheeting, or recycled plastic sheeting. Ensure proper overlap to prevent leaks. Secure the roofing material using appropriate fasteners.

Adding Siding and Doors

Consider adding siding to the exterior walls for improved weather resistance and aesthetics. Recycled materials like more pallet wood or repurposed materials can be used for a cohesive aesthetic. Install a door using reclaimed pallet boards or purchased lumber. Ensure the door is securely hung and provides a weathertight seal. Adding hinges and a latch completes the door assembly.

Interior Finishing

Add interior shelving or hanging racks to maximize storage space. Consider painting or staining the interior walls and shelving for protection and aesthetic enhancement. Ensure adequate ventilation to prevent moisture buildup and mold formation. Adding a small window provides additional natural light and ventilation.

Safety Considerations

Throughout the construction process, prioritize safety. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and sturdy footwear. Use caution when handling power tools and sharp objects. Follow all manufacturer's instructions for power tools and ensure the work area is well-lit and free of obstacles. Obtain assistance when necessary, especially for lifting heavy objects.

Building a pallet shed is a rewarding project that combines resourcefulness with practical skills. By carefully following these free pallet shed plans and prioritizing safety, you can construct a functional and durable garden storage solution that enhances your outdoor space while minimizing environmental impact.